OVERVIEW OF REUSE WASTEWATER

What is reuse wastewater?

The operation of industrial plants today uses a huge amount of clean water every day to produce and use for different processes. This creates a large volume of wastewater that needs to be treated to meet standards for wastewater treatment systems before being discharged into the environment.

Therefore, the problem of using a lot of clean water while the amount of wastewater discharged into the environment is large, offers businesses a solution on how to reuse this amount of wastewater to become a source of clean water for the production process.

Wastewater reuse is the process of using technologies and equipment to treat wastewater after discharge into clean output water in accordance with standards for recovery and use for production and house cleaning. workshops, cooling systems, watering plants in factories and industrial parks.

Currently, the reuse of wastewater helps to effectively use clean water resources, solve the problem of water shortage in the world, and avoid waste and loss of clean water in the production and business process of enterprises.

Since then, water reuse brings long-term economic value to businesses, increases product value and brand recognition, contributes to creating and maintaining the balance of the ecological environment with the sustainable development of the business.

PURPOSE AND APPLICATION OF REUSE WASTEWATER

At Hoa Phat Eco, we have many years of research on water reuse technologies, solutions to reuse industrial wastewater after treatment to become a source of clean water that meets appropriate output standards that allow reuse. Used for production processes, cooling systems, boilers.

In addition, the solution to reuse domestic wastewater can not only treat wastewater for use in the process of watering plants and street cleaning, but also can treat it up to standards into drinking water.

Waste water reuse technology of Hoa Phat Eco Company is installed and widely applied to the following industries:

– Reuse of textile dyeing and textile wastewater

– Reuse of food and pharmaceutical wastewater

– Reuse of steel production, electroplating wastewater

– Reuse of leachate, waste treatment factory

– Reuse of breeding farm wastewater

– Reuse industrial park wastewater

ADVANTAGES AND BENEFITS OF WASTE WATER REUSE

- Conserve fresh water resources

- Reduced processing and energy costs

- Reduce waste volume and cost

- Minimizing the environmental impact of wastewater discharge

- Increase product value and advantage of corporate brand identity: green certificate, certificate of environmental companionship, meeting ISO quality and environmental management standards, …

WHICH COMPANY PROVIDES THE BEST WASTEWATER REUSE SERVICE IN VIETNAM?

With an understanding of water reuse solutions, a future vision in the effective application of wastewater reuse technology in the environmental field, Hoa Phat Eco is a contractor providing water reuse services packaged, turnkey waste for factories and businesses including:

– Consulting on choosing suitable wastewater reuse capacity: Currently in Vietnam, the cost of clean water is still not too high compared to the world, so businesses often choose the option to reuse a part of the wastewater. wastewater capacity, up to about 80% of generated wastewater capacity.

– Consulting on selection of wastewater reuse technology suitable to the characteristics of each production industry and depending on the capacity that customers need to reuse.

– Design drawings, site planning, waste water reuse chain system

– Construction, construction of wastewater reuse system, equipment installation, automation electricity

– Service of operation, training and transfer of water reuse technology

POPULAR WASTEWATER USE TECHNOLOGIES CURRENTLY

With the advantage of a design team, technology research and always attaching importance to quality first, we have been working with leading manufacturers in the world to bring reusable equipment and technology. suitable wastewater for effective application to current reuse needs.

In order for customers to better understand the wastewater reuse process as well as choose the right reuse technology for their needs, Hoa Phat Eco’s technical team would like to share some outstanding technologies that we I am researching and applying for wastewater reuse and difficult wastewater treatment projects in Vietnam:

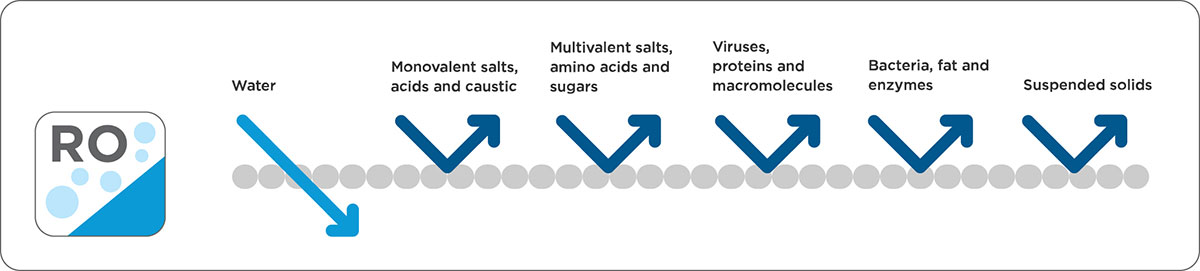

1. Waste water reuse technology by RO reverse osmosis membrane system:

This is the best wastewater reuse technology today, widely applied by Hoa Phat Eco and highly effective for many reuse projects in Vietnam, affirming our capacity and experience. in the field of general contractor for design and construction of water reuse and industrial wastewater treatment systems.

The RO water reuse system is designed, researched and perfected by Hoa Phat Eco in Vietnam with the strictest standards, with the cooperation of technology and equipment from from the world’s leading RO membrane manufacturers such as:

- RO Dupont Filmtec, Dow Membranes

- Nitto Hydranautics Membranes

- Toray Membranes

- Pentair, Pentex Membranes

- Microdyn Nadir Membranes

- Membranium Membranes

- Parker Membranes

- Axeon Membranes

- Other membranes maker: Ropur, TriSep, LewaBrane, LG RO Elements, Synder, …

In addition, Hoa Phat Eco’s water reuse system is also in line with Vietnam’s national standards such as electrical design standards, mechanical standards for anti-corrosion, standards for safety and hygiene in applications. foods such as breweries, food factories, pharmaceuticals, etc.

Advantages of wastewater reuse system by RO membrane technology:

Wastewater after passing through the UF Ceramic filter system will be fed to the RO reverse osmosis membrane system with a recovery rate of up to 90%. The RO reverse osmosis membrane system includes a high-pressure pump system and measuring devices to control parameters. A membrane cleaning system (CIP) is also integrated. Anti-scale chemicals are added to protect the membrane along with a pH adjuster. The whole system is controlled automatically by PLC, HMI programming.

Wastewater with many different components creating concentrations of BOD, COD, color … after passing through the RO membrane, it will be separated into 2 channels: clean water that permeates the membrane and the part that cannot pass through the membrane, which is organic and inorganic substances. other molecules.

The process of separating water from wastewater by RO membrane is a physical separation process. Thoroughly restore contaminated water sources. Does not increase the amount of contaminated sludge due to the process of using more chemicals for treatment.

Hoa Phat Eco’s RO membrane module uses specialized membranes in wastewater filtration. The difference of RO Membrane Module provided by Hoa Phat Eco is different from other RO membranes that is due to the design of the tube module structure combined with open channel and eddy flow to be able to handle wastewaters with much higher concentrations of pollutants than conventional membrane modules.

P&ID diagram of Hoa Phat Eco’s wastewater reuse technology:

Advantages of wastewater reuse system by RO membrane technology:

– The system is designed to be able to operate at high frequency, operating pressure up to 160bar

– Open channel configuration allows for low flow resistance and low concentration polarization, minimizing fouling rates on the membrane

– High rejection and high recovery with low energy costs (up to 99.6%)

– The frame of the system is welded, assembled in stainless steel, for long time use and low maintenance cost.

– RO systems are automatically adjusted for pressure and flow. This allows the system to consistently deliver the maximum achievable power at the design temperature and salinity at all times.

– Designed to operate with much higher inlet water quality than traditional RO membranes but maintain a long membrane life (3 – 5 years or more) due to optimal open channel design

– Low cost of chemicals to clean RO membranes. Chemicals are only used to clean the membrane. The system is equipped with automatic membrane cleaning.

– The system is equipped with an automatic fault alarm and safety shutdown system to protect and avoid damage to the system due to external factors or improper operation.

– The system is fully automatic control

2. MABR Technology:

MABR biofilm technology uses passive aeration and biofilm-based sterilization to provide primary and secondary treatment, bringing the treated wastewater to a suitable standard for reuse in irrigation. This technology is especially suitable for reuse in municipal and residential wastewater treatment. MABR technology uses up to 90% less energy for aeration than conventional technologies resulting in significant reductions in operating costs.

3. MF microfiltration and UF ultrafiltration membrane technology:

Membrane technology MF and ultrafiltration UF is a technology that uses low pressure membranes to separate large solids, suspended solids, suspension properties and purification of dissolved solids. This technology is widely applied in the reuse of wastewater after treatment for road sanitation, irrigation, and toilet use.

4. NF nanofiltration membrane technology:

This is a technology that uses a membrane filter with medium pressure to separate organic compounds and ions in water. It is required that when using NF nanofiltration technology, it is necessary to install a pre-filter system to remove large solids so that the rear system is not clogged and clogged, minimizing the frequency of washing membrane.

The advantage of this technology is that the treated water is of very good quality, so it can be reused for high output water quality requirements such as feed water for the production of food, milk, beer, wine, and water refreshments or can make drinking water.

Hoa Phat Eco is a contractor that designs and constructs a package of technological solutions for reuse wastewater. With the capacity of consulting and applying the most advanced technologies to help customers choose the most suitable waste water reuse plan, with reasonable investment costs, ensuring stable and effective operation, contribute to accompanying enterprises and factories in saving clean water resources and protecting the environment.